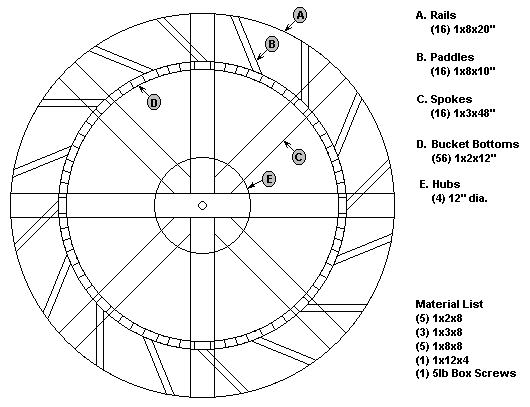

- I cut 8 pieces, each was 20" long and had 22.5 degree on both ends. For smaller or larger wheels this measurement will vary. I used 1x8 board for a 4' wheel, larger wheels use 1x12 board. Smaller wheels use 1x6.

- Drill 2 dowel holes (about 2" apart) in each end of the 8 pieces. In bigger wheels put 3 dowels in each end.

- Glue & Assemble the 8 pieces together to form an octogon.

- I clamp them to a table to make sure all sides are equal.

- Repeat steps 1-4 for second octogon. (with wheels bigger than 4' diameter, make 4 octogons).

- using a stick and a pencil, mark out the inside diameter and outside diameter on the octogon.

- To cut the inside & outside diameters, I attached my router to a board. The board was anchored to a bolt at the center of the wheel. This allowed the router to swing around the wheel like the hands of a clock. I cut about 1/4" at each pass. If you dont have a router, use a resiprocating saw.

- Cut 22 pieces, each is 10" long using the same size board you cut the rails from. Cut a 45 degree angle on one end. With a larger wheel you may want 24 or 30 paddles. 16 for a smaller wheel. About 6-8 inches apart looks the best.

- Divide the ouside diameter of your wheel by the number of paddles. Make marks along 2 of the rails. Example: The ouside diameter of a 4' wheel is 150.72 inches. Divide that by 22 and that puts the paddels about 6 7/8" apart.

- Install the paddles at each mark by screwing through the first rail into the paddle. They should be at 45 degree angles to the rail. The top part of the paddle should be even with the outside rim of the rail, the bottom of the paddle (the end with the 45deg. cut should match the bottom). Dont forget to pre-drill all holes.

- Take the remaining 2 rails and attach them, one to each side of the wheel. Make sure you rotate the joints. Attach these screwing from the inside of the wheel. That way you dont have any screws showing from the outside.

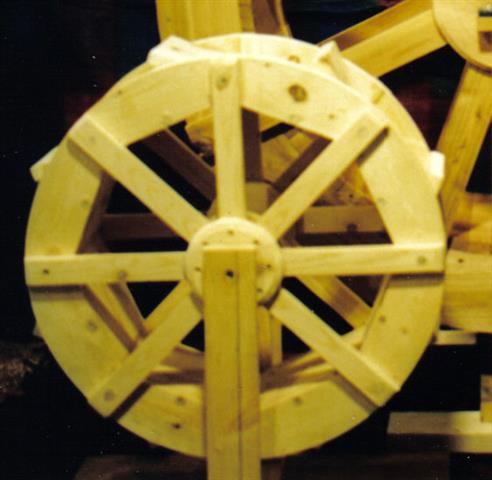

- I used 1x3's. Cut 4 pieces the same lengh as the diameter of your wheel. These will be the long spokes.

- Use a router to notch the center of the boards. This will allow you to put two together and form a "plus sign".

- Cut 8 pieces the same length as the radius of the wheel. These will be the short spokes. Cut a 45 degree angle on both corners of one end (so that it looks like an arrow.

- I used 1 1/2" wide boards. They were 1" thick but thinner is better. Divide The inside circumfrence of wheel (in inches) by the width of your boards. Example: The inside diameter of a 4' wheel is 40 inches, so the circumfrence is 104.67 inches, divide by 1.5 = 70 boards. Cut the boards the same width as the outside diameter of the wheel.

- Drill a hole in each end of each board, then screw to the inside of the rails. Glue each piece on the bottom and side for a tight fit.

- Cut 4, 12" diameter hubs.

- Screw 2 long spokes to one hub. Screw throught he spokes into the hub not the other way around. That way your screws will be hidden.

- Screw 4 short spokes to that hub. Same way. Measure distances to ensure they are all even.

- Cap that off with the second hub peice. So you should have the spokes sandwiched between two hub pieces. To attach this second hub, screw from the outside of the hub into the spokes. Reverse of before. These screws will be visable, but you will be putting this side of the hub to the inside of the wheel.

- Screw spokes to wheel. Make sure the hub is dead center.

- Repeat for other side of wheel.

- Drill holes in hub for axle. And you are done.

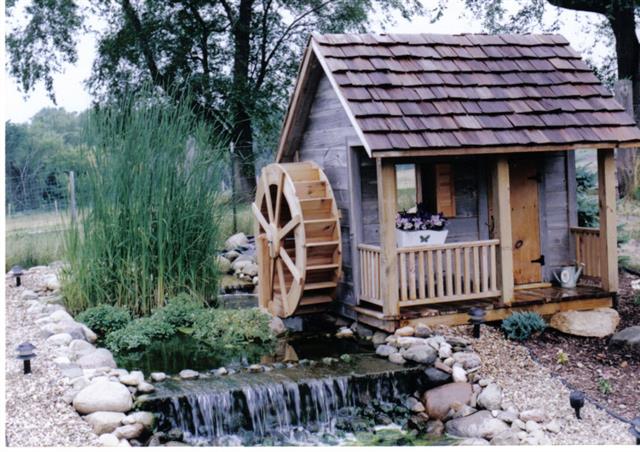

The axle is a 1/2" galvanized pipe (like gas pipe). A metal flange is welded to the pipe and the wheel is connected to the flange. The axle rotates on pillow bearings.

The sleuce is made of 1x8 Cedar also. The interior of the sleuce is lined with a piece of 45mil EPDM rubber, which is folded in half. The water does not come into contact with the wood. The rubber extends out past the wood about 1/4" to provide a nice waterfall. The wood has to rough and thick to do this. A sharp edge creates the best water sheen.

The pump which turns the waterwheel is a tiny 300gph Little Giant fountain pump. It draws water from the millpond, and then pumps it to the sleuce through 1/2" cpvc pipe. The pipe is connected to the rubber inside the sleuce using my standard Pipe Boot fitting.